Best Practices for Cleaning and Maintaining GRP Grating

Introduction

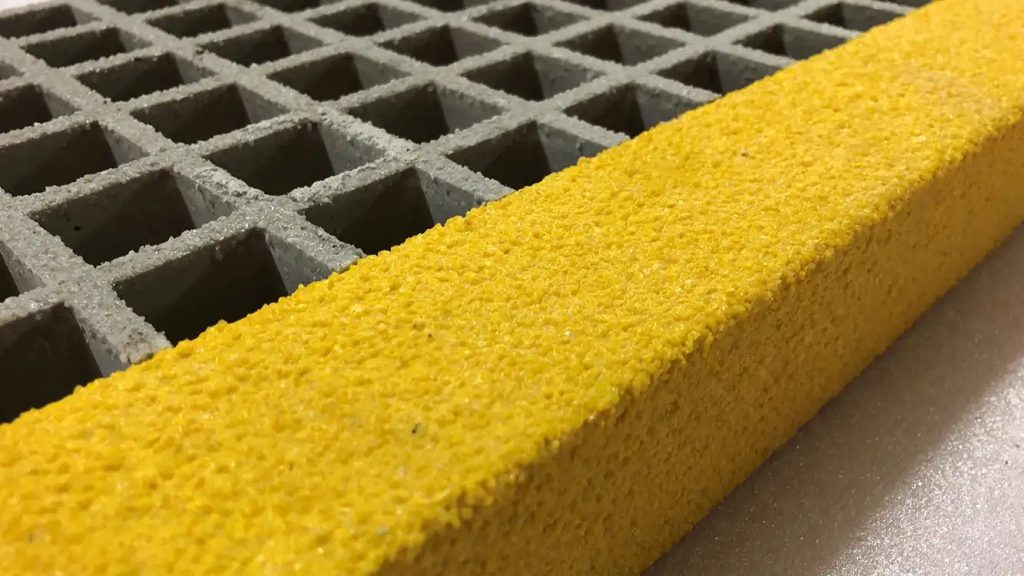

Glass Reinforced Plastic (GRP) materials have become essential across numerous industries due to their outstanding strength, corrosion resistance, and longevity. Among these materials, GRP Grating stands out as a reliable solution for walkways, platforms, and environments where safety and durability are top priorities. To ensure long-term performance and preserve its unique advantages, understanding the best practices for cleaning and maintaining GRP Grating is essential.

Proper upkeep not only improves safety but also extends service life, reduces replacement costs, and maintains a professional and clean appearance across industrial, commercial, and marine settings. This comprehensive guide explains the most effective maintenance strategies, cleaning methods, inspection routines, and preventive measures to help you get the most out of your GRP Grating.

Why Maintenance of GRP Grating Matters

Maintaining GRP Grating is not just about appearance—it directly affects performance, safety, and compliance.

Enhanced Longevity

Regular cleaning prevents buildup of dirt, chemical residue, oils, and debris that can weaken the surface or reduce slip resistance. With the right practices, GRP Grating can last decades.

Improved Safety Performance

The anti-slip properties of GRP Grating are among its biggest advantages. However, when contaminants accumulate, the slip resistance can diminish.

Cost Savings

A well-maintained GRP Grating system reduces the frequency of replacements and repairs. Routine inspections and cleaning are far more affordable than full replacements.

Regulatory Compliance

In industries where safety regulations are strict—such as marine, industrial, petrochemical, and wastewater—cleaning and maintenance help meet safety standards consistently.

Understanding the Unique Structure of GRP Grating

GRP Grating is made from woven fiberglass reinforced with thermosetting resin, creating a lightweight and corrosion-resistant alternative to steel grating.

Key Benefits Related to Maintenance

- Corrosion resistance: No rusting or oxidation.

- Low maintenance: Requires minimal upkeep compared to metal alternatives.

- High chemical resistance: Ideal for aggressive environments.

- UV stability: Maintains strength and color over time.

These features make GRP Grating an excellent long-term investment, provided it is cared for correctly.

Types of GRP Grating and Their Maintenance Needs

Different types of GRP Grating may require slightly different cleaning or inspection methods.

Moulded GRP Grating

Moulded GRP Grating features a uniform, robust structure.

- Maintenance need: Simple cleaning; should be inspected for surface wear.

Pultruded GRP Grating

Pultruded GRP Grating is known for high load-bearing capacity.

- Maintenance need: Inspect for structural integrity and bonding.

Covered GRP Grating

This type includes a solid top layer.

- Maintenance need: Ensure covered surface doesn’t show wear or delamination.

Best Practices for Cleaning GRP Grating

Cleaning GRP Grating regularly keeps it in optimal condition. Below are the most effective cleaning techniques.

Routine Cleaning Methods

Hosing & Pressure Washing

One of the easiest and most efficient cleaning methods is using a hose or pressure washer.

- Helps remove dust, dirt, and light debris.

- Restores the anti-slip surface.

- Suitable for all types of GRP Grating.

Tip: Keep pressure below 3000 PSI to avoid surface damage.

Soft Bristle Scrubbing

For tougher buildup, use warm water, mild detergent, and a soft-bristle brush.

- Effective for grease, algae, and chemical residue.

- Gentle enough to preserve the anti-slip surface of GRP Grating.

Using Industrial Cleaners

In industrial environments, heavy contaminants require stronger cleaning agents.

- Always choose cleaners compatible with GRP Grating materials.

- Avoid harsh solvents like MEK or acetone, which can damage resin.

Deep Cleaning for Stubborn Contaminants

Removing Oil and Grease

Oil is common in industrial settings and may reduce slip resistance.

- Use biodegradable degreasers.

- Rinse thoroughly to restore traction.

Eliminating Algae and Moss Growth

In marine, outdoor, or humid environments, algae growth is common.

- Use chlorine-based solutions diluted with water.

- Pressure wash after treatment.

Tackling Chemical Spills

Industries handling chemicals should clean spills immediately.

- Use pH-neutralizing solutions where appropriate.

- Inspect the GRP Grating surface afterward for potential damage.

Preventive Maintenance Strategies

Preventive maintenance ensures your GRP Grating continues to perform at its best.

Regular Inspection Schedule

Create a structured inspection routine.

Monthly Inspections

- Look for surface wear and loss of anti-slip properties.

- Remove visible debris from the GRP Grating surface.

Quarterly Inspections

- Ensure the grating is securely fastened.

- Check clips and support frames.

- Inspect for cracks or resin degradation.

Annual Inspections

- Perform deep cleaning.

- Check load-bearing areas carefully.

- Evaluate the overall condition of the GRP Grating system.

How to Identify Damage in GRP Grating

Spotting problems early prevents costly repairs.

Surface Wear

Loss of grit on the surface lowers slip resistance.

Cracks or Fractures

Signs of impact damage or overloading.

Resin Blistering

Occurrence due to trapped moisture or chemical exposure.

Delamination

Rare in high-quality GRP Grating, but possible if exposed to severe mechanical stress.

Corrective Maintenance: What to Do When Issues Arise

If inspections uncover damage, timely corrective action is essential.

Repairing Minor Damage

- Small chips can be patched using repair resin kits.

- Reapply anti-slip grit coating if surface wear is mild.

Handling Major Damage

If structural integrity is compromised:

- Replace the affected GRP Grating panel immediately.

- Check support structures for hidden damage.

Reinforcing Grating

If high-load equipment has stressed the grating:

- Install reinforcement bars.

- Consider upgrading to a heavier-duty GRP Grating type.

Environmental Factors That Affect Maintenance

Marine Environments

- Saltwater can accelerate wear on the surface coating.

- Frequent rinsing is recommended.

- Inspect support frames for corrosion even though GRP Grating itself won’t rust.

Industrial Environments

- High chemical exposure requires more frequent cleaning.

- Ensure chemical compatibility of all cleaning agents.

Outdoor Settings

- UV exposure may cause long-term color fading, but not structural degradation.

- Trim surrounding vegetation to prevent debris buildup on GRP Grating.

Safety Precautions During Cleaning and Maintenance

To maintain workplace safety, follow these guidelines:

Protect Personnel

- Wear gloves, safety boots, and goggles.

- Use harnesses when cleaning elevated GRP Grating.

Maintain Stable Work Conditions

- Avoid cleaning in wet or windy conditions if the grating is elevated.

- Ensure proper signage if cleaning in active industrial areas.

Use Safe Cleaning Products

- Avoid flammable or corrosive chemicals.

- Ensure all products are safe for GRP Grating surfaces.

Tips to Extend the Lifespan of GRP Grating

Install Proper Drainage

Standing water accelerates dirt buildup. Proper drainage reduces cleaning frequency.

Avoid Excessive Load

Even though GRP Grating is strong, exceeding load capacity shortens lifespan.

Conduct Professional Audits

Annual professional inspections ensure compliance with industry standards and safety regulations.

Use Protective Coatings

Anti-slip regrit coatings or resin surface treatments rejuvenate old GRP Grating.

Common Mistakes to Avoid

Even high-quality GRP Grating may suffer if mistreated.

Using Harsh Chemicals

Solvents may damage resin layers. Always check compatibility charts.

Overusing High-Pressure Washing

Extremely high pressure can dislodge gritty surfaces.

Ignoring Small Damage

Minor issues can quickly escalate if not addressed.

Allowing Debris Accumulation

Leaves, oil, and industrial residue reduce slip resistance and cause staining.

Conclusion

GRP Grating is a long-lasting, durable, and low-maintenance solution for various applications across industrial, marine, and commercial sectors. However, like any material, it still requires proper care to maximize performance and safety. Following the best practices for cleaning, inspection, and preventive maintenance will ensure your GRP Grating remains in excellent condition for years to come. By using appropriate cleaning techniques, performing regular inspections, addressing damage promptly, and considering environmental factors, you can extend the lifespan of your GRP Grating significantly. With these strategies in place, your installation will continue to deliver exceptional durability, safety, and reliability.